Introduction

Sodium formate is an important support chemical in the leather industry. It is widely used during tanning and wet-end processing to control pH, improve chrome fixation, and protect hides from bacterial damage. Because it works gently and reliably, leather manufacturers prefer sodium formate for stable production and consistent leather quality. It helps improve efficiency without adding complexity to daily operations.

Core Chemical Functions in Leather Processing

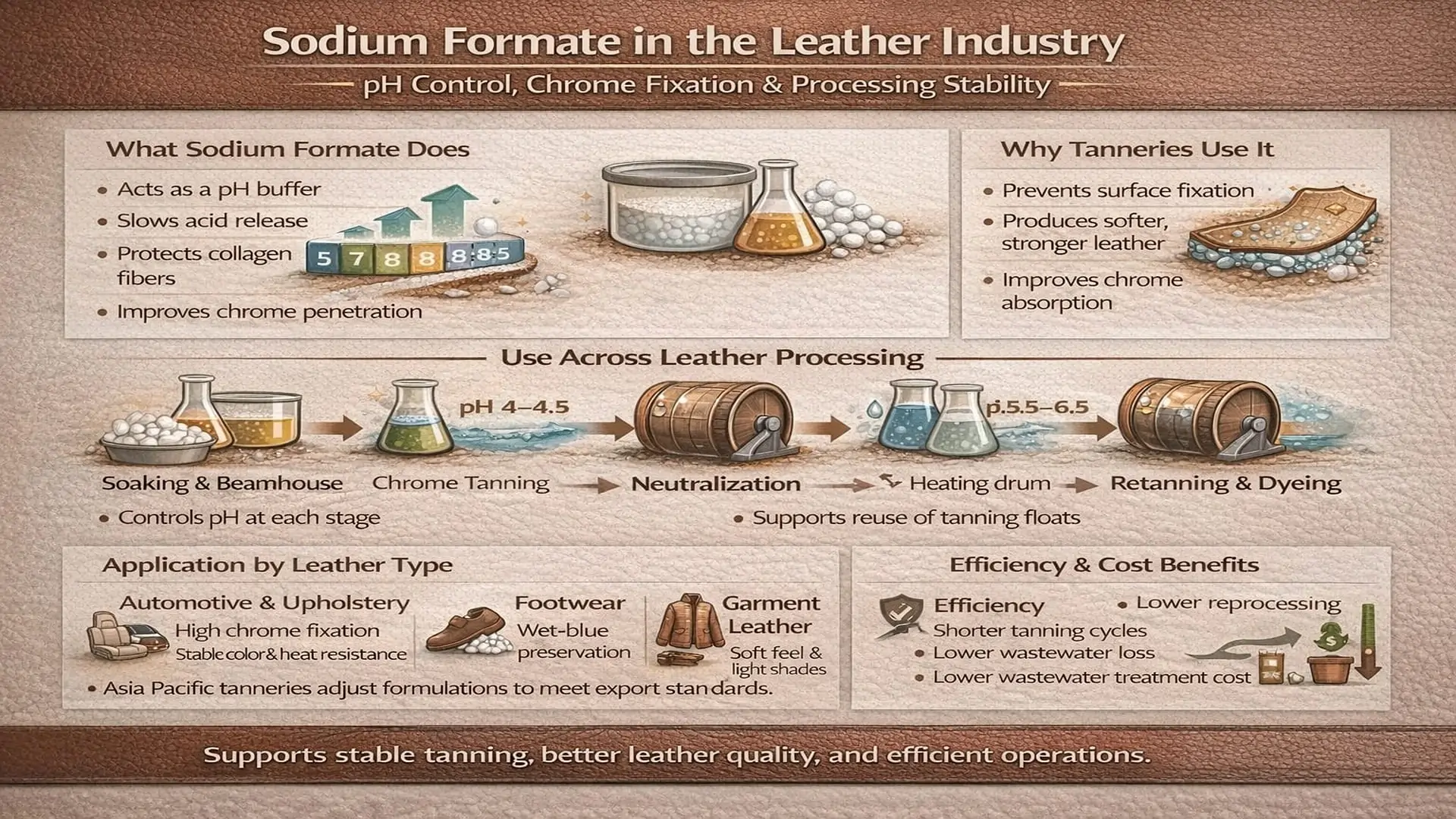

Sodium formate mainly works as a pH buffer. It helps keep the tanning bath stable, especially in acidic conditions where sudden pH changes can damage collagen fibers. By slowing down pH reduction, sodium formate allows tanning chemicals to enter the hide evenly, avoiding surface fixation and weak inner layers.

In chrome tanning, sodium formate is often called a “camouflage acid.” Instead of lowering pH too fast, it releases acidity slowly. This protects the hide structure and improves chrome absorption. As a result, leather becomes softer, stronger, and more uniform.

Sodium formate also has mild preservative properties. It limits bacterial growth during soaking, storage, and wet-blue handling. This helps prevent bad odors, grain damage, and loss of hide weight. In addition, it supports chrome fixation, reducing leftover chromium in wastewater and improving environmental performance.

Use in Key Leather Processing Stages

Sodium formate is used across several important steps in leather production. In early beamhouse operations, it helps control pH during soaking and liming. This slows bacterial attack and keeps hides plump and stable before tanning begins.

During chrome tanning, sodium formate is added to the tanning float to guide pH from strongly acidic toward the correct fixation range. Typical use levels allow chrome salts to penetrate fully before binding to collagen. This improves tanning efficiency and reduces chrome loss.

After tanning, sodium formate supports neutralization. It helps bring pH to the right level for retanning, dyeing, and fatliquoring. This avoids over-neutralization, which can cause loose grain or poor dye uptake. In vegetable tanning, sodium formate is used at lower levels to help tannins move evenly into the hide.

Many tanneries also reuse tanning floats. Sodium formate supports these closed-loop systems by keeping reused baths stable and helping meet wastewater discharge rules.

Differences Across Leather Segments

Sodium formate use varies depending on leather type and final application. In automotive and upholstery leather, precise pH control is critical. Sodium formate helps achieve high chrome fixation and stable color, which are needed for long service life and heat resistance.

In footwear leather, sodium formate is often used as a preservative in wet-blue hides that are stored or shipped. This reduces spoilage risk during transport and storage. For garment leather, controlled use helps maintain softness and light color shades.

Compared with textiles, where sodium formate mainly stabilizes dye baths, leather processing focuses more on protecting collagen and improving tanning depth. Other industries, such as oil drilling or pharmaceuticals, use sodium formate at higher purity or higher dosage, while leather production favors cost-effective industrial grades.

Operational Value and Efficiency Benefits

Sodium formate improves production efficiency by reducing tanning time and lowering reprocessing rates. Stable pH control helps shorten tanning cycles and reduces energy use during heating and basification. Consistent results also lower the risk of rejected hides.

From a cost point of view, sodium formate offers good value because one product performs several roles. It replaces stronger acids, separate buffers, and some preservatives. Better chrome fixation also reduces chemical loss and lowers wastewater treatment costs.

For large tanneries, sodium formate supports zero-liquid-discharge systems by improving chrome recovery and lowering sludge volumes. Improved hide preservation and tanning quality can increase usable leather yield, which directly improves margins.

Sourcing and Quality Considerations

When sourcing sodium formate, leather producers focus on purity, low chloride content, and minimal heavy metals. Poor-quality material can cause stains, uneven tanning, or processing instability. Flake or powder forms are preferred for easy dosing and long shelf life.

Most global supply comes from Asia, with China and India as key producers. Bulk packaging supports cost-efficient transport to major leather hubs such as Indonesia, Vietnam, and India. Buyers usually request certificates of analysis to confirm quality and compliance with leather safety standards.

Conclusion

Sodium formate plays a vital role in modern leather production by improving pH control, tanning efficiency, and hide preservation. Its gentle action protects collagen structure while supporting strong chrome fixation and consistent leather quality. With added benefits in cost control, wastewater management, and supply reliability, sodium formate remains a trusted and widely used chemical across the leather industry.

Leave a Comment