Introduction

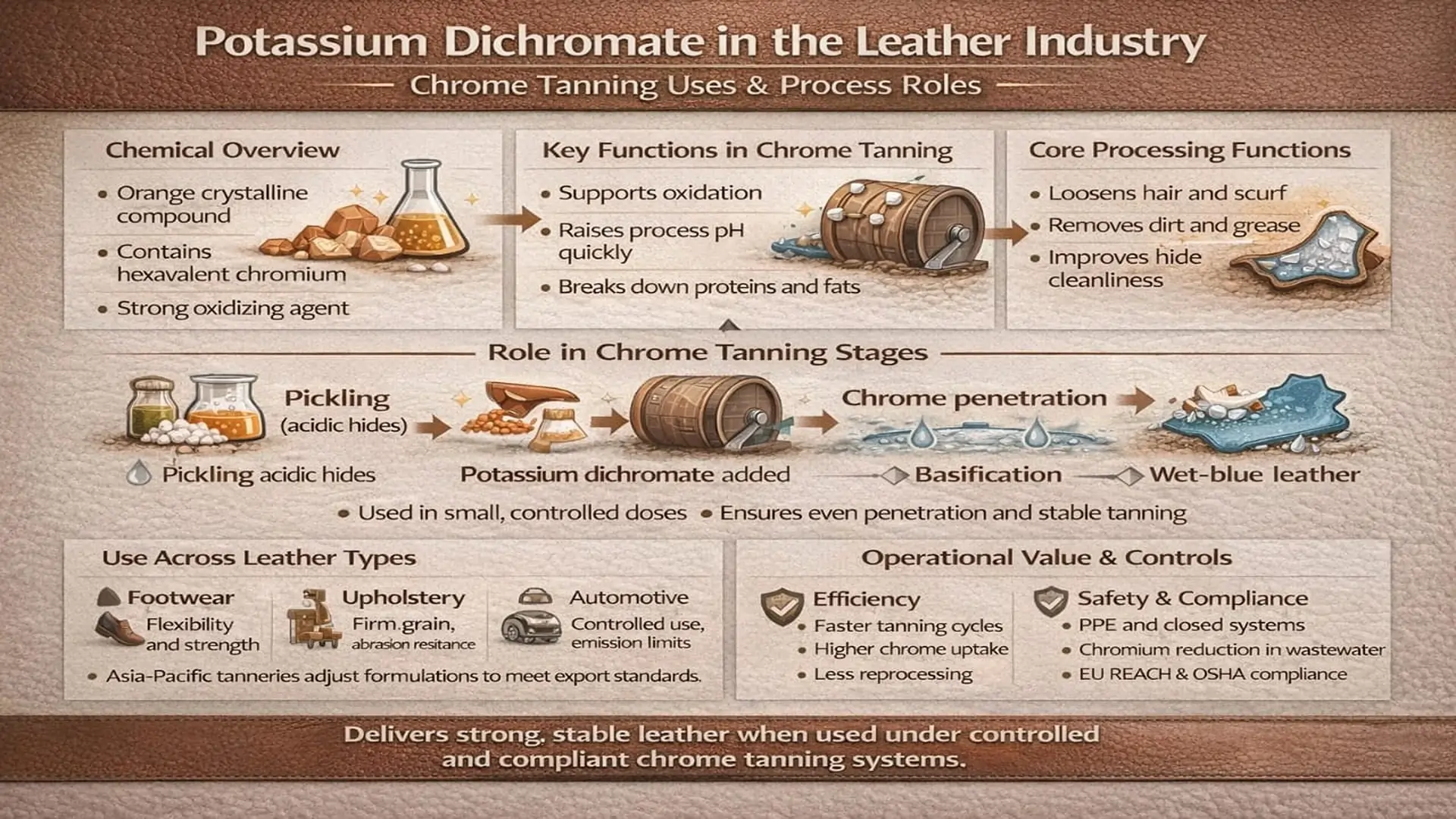

Potassium dichromate is an important chemical used in the leather industry, mainly in chrome tanning processes. It helps convert raw hides into durable and stable leather by supporting oxidation and chrome fixation. Even with strict controls on hexavalent chromium, many tanneries continue to use potassium dichromate for specific industrial needs where performance and consistency are critical.

Leather manufacturers and procurement teams value potassium dichromate for its reliable results in wet-end processing, especially in large-scale production where uniform tanning quality is required.

Chemical Properties and Core Functions

Potassium dichromate is an orange crystalline compound that contains hexavalent chromium. Its main function in leather processing is oxidation. During chrome tanning, it helps strengthen collagen fibers by supporting chemical bonding within the hide structure. This process improves heat resistance, shape stability, and resistance to shrinkage.

The material dissolves easily in water and remains stable under normal tanning temperatures. This allows it to perform consistently in rotating drums and controlled tanning baths. Potassium dichromate is not used as a preservative or reducing agent in leather production. Its role is focused on improving chrome fixation and fiber stability during tanning.

Role in Chrome Tanning Processes

Potassium dichromate is added after pickling, once the hides are fully prepared and acidic. At this stage, it supports the oxidation needed for proper chrome penetration and bonding. The chemical is used in small, controlled amounts and is followed by acids or masking agents to guide even distribution through the hide.

During drum tanning, controlled temperature and pH allow potassium dichromate to work efficiently without damaging the collagen structure. This results in strong, evenly tanned wet-blue leather with good color and mechanical strength.

In some retanning operations, small amounts of residual dichromate improve dye uptake and color consistency. This is especially useful for leather used in upholstery and automotive interiors, where uniform appearance is critical.

Integration Across Tanning Stages

Chrome tanning involves penetration, basification, and fixation. Potassium dichromate supports the penetration stage by stabilizing chrome movement into the hide fibers. As pH increases during basification, chrome complexes form and bind firmly to collagen.

In combination tanning systems, such as chrome-vegetable tanning, potassium dichromate is used at lower levels to support structure without overpowering natural tanning agents. Careful monitoring of pH and chrome exhaustion helps reduce waste and ensures high process efficiency.

After tanning, controlled heat treatment helps lock chrome complexes into place. This reduces the need for repeat treatments and improves overall production speed.

Differences Across Leather Segments

Potassium dichromate use varies by leather type. Footwear leather often uses higher amounts to improve softness, flexibility, and resistance to repeated bending. Upholstery leather uses lower levels to achieve firmer grain and better abrasion resistance.

Automotive leather places strict limits on emissions and fogging, so potassium dichromate use is carefully controlled or partially replaced with alternative chrome sources. Garment and glove leathers may use it later in processing to improve color stability and hygiene.

Export-focused tanneries, especially in Asia-Pacific, adjust formulations to meet international regulations by limiting hexavalent chromium in effluents and finished leather.

Operational Value and Efficiency

Potassium dichromate improves tanning efficiency by speeding up collagen bonding and reducing processing time. Faster tanning cycles allow higher throughput without sacrificing quality. High chrome uptake means less waste and lower sludge volumes in wastewater treatment.

Cost control is another advantage. Compared to some specialty tanning chemicals, potassium dichromate offers stable pricing and predictable performance. Improved leather yield and reduced reprocessing also support better margins.

Its stability in acidic conditions helps avoid precipitation and drum fouling, reducing maintenance needs and downtime.

Regulatory and Safety Considerations

Because potassium dichromate contains hexavalent chromium, strict safety and environmental controls are required. Tanneries use protective equipment, proper ventilation, and closed handling systems to reduce worker exposure.

Effluent treatment systems convert hexavalent chromium into safer trivalent chromium before discharge. Compliance with EU REACH, OSHA limits, and local environmental laws is essential for continued use.

Many producers track usage and emissions closely through digital systems to support audits and export certification.

Conclusion

Potassium dichromate remains a valuable chemical in the leather industry, especially for chrome tanning applications that demand strength, heat resistance, and consistent quality. When used in controlled amounts and supported by proper safety and wastewater treatment systems, it delivers strong operational benefits. Despite growing regulatory pressure, potassium dichromate continues to play a role in producing high-value leather where performance and durability are critical.

Leave a Comment