Introduction

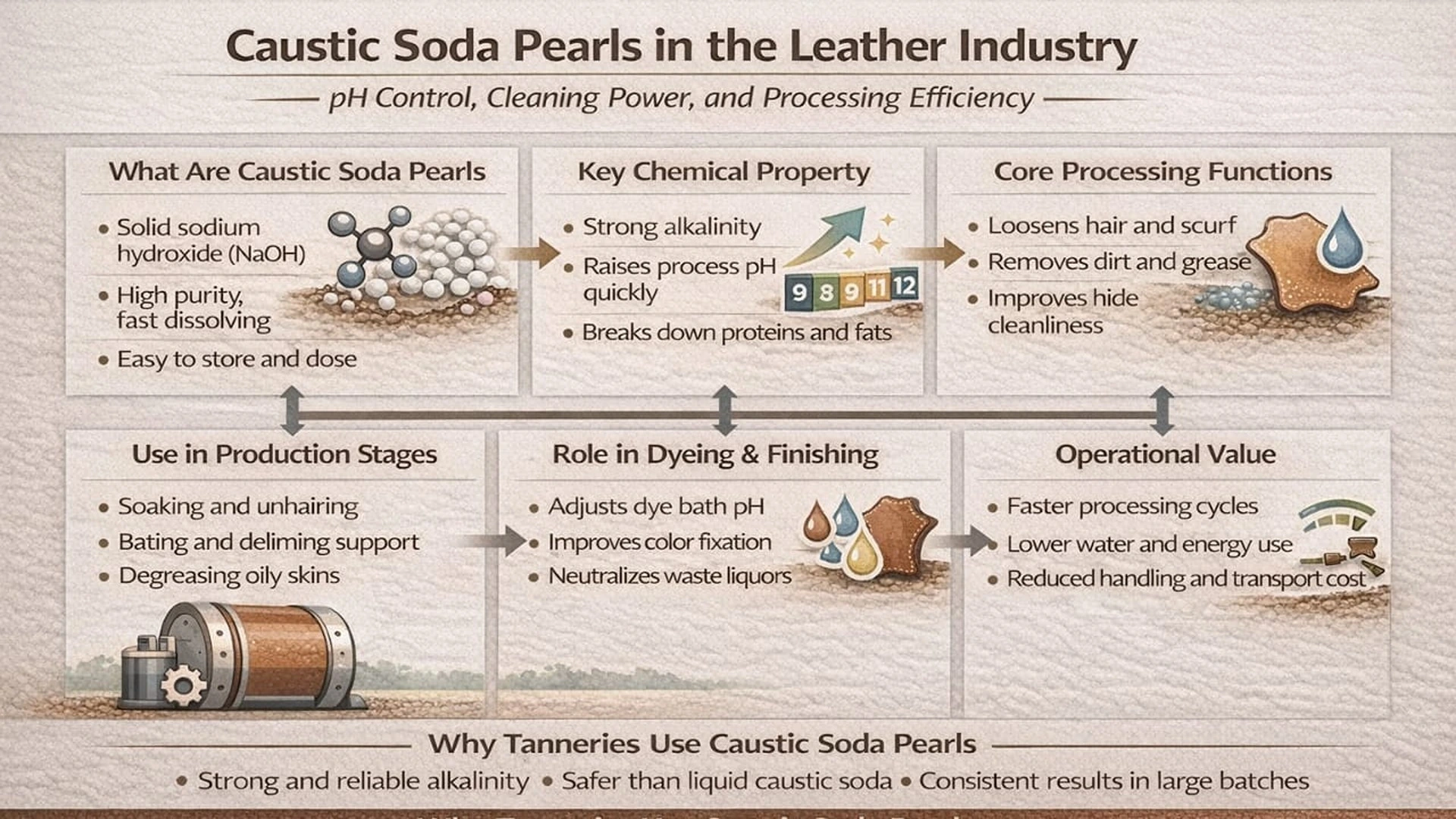

Caustic Soda Pearls are a core chemical used in leather manufacturing, especially during beamhouse and finishing stages. Made from solid sodium hydroxide with high purity, these small granules dissolve quickly and provide strong alkalinity for hide treatment. Tanneries rely on caustic soda pearls because they are easy to store, safer to handle than liquid forms, and effective in large-scale processing.

In leather production, precise pH control is critical. Caustic soda pearls allow operators to adjust alkalinity accurately, which helps protect hide structure, improve cleanliness, and ensure stable processing results.

Chemical Properties and Physical Form

Caustic soda pearls are solid, round granules of sodium hydroxide with purity levels close to 99 percent. When dissolved in water, they create a strong alkaline solution with a very high pH. This strong alkalinity is needed to break down unwanted proteins, fats, and residues on raw hides.

Compared to flakes or liquid caustic soda, pearls produce less dust and are easier to measure. This reduces handling risks and improves safety in humid tannery environments. High purity is important in leather processing, as excess salts or iron can cause stains, uneven swelling, or damage to light-colored leather.

Core Functions in Leather Processing

The main role of caustic soda pearls in leather processing is pH control. They raise alkalinity during early processing stages, helping loosen hair, dissolve surface proteins, and remove dirt and grease.

Caustic soda also helps break down keratin in hair and scurf, making hair removal faster and more complete. Unlike sulfide-based chemicals, it does not release toxic hydrogen sulfide gas, which improves workplace safety and air quality.

Another key function is degreasing. Caustic soda converts natural fats into soap-like compounds that can be washed away. This prevents oily patches that interfere with dyeing and finishing later in the process.

Use in Key Production Stages

During soaking and unhairing, caustic soda solutions help swell hides and open up the fiber structure. This allows dirt, blood, and hair to be removed more easily. Proper control of temperature and concentration ensures effective cleaning without damaging collagen fibers.

In bating and deliming, caustic soda supports enzyme activity by keeping the process alkaline. This helps remove unwanted proteins and improves softness and flexibility in the final leather. It also helps neutralize excess lime before pickling, preparing hides for tanning.

For greasy skins such as sheep and goat hides, caustic soda plays an important role in degreasing. It helps remove natural oils that can block dye penetration. In washing stages, it keeps pH stable, ensuring even cleaning across all hides in a batch.

During dyeing and finishing, caustic soda adjusts the pH of dye baths to improve color fixation. It also helps neutralize waste liquids from fatliquoring and finishing, supporting compliance with environmental discharge limits.

Operational Value and Cost Efficiency

Caustic soda pearls help speed up processing by shortening unhairing and cleaning cycles. Faster reactions reduce water and energy use, lowering operating costs. Their even dissolution ensures stable pH throughout large batches, reducing the risk of uneven processing or hide rejection.

Because pearls are solid, transport and storage costs are lower than liquid caustic soda. One ton of caustic soda pearls can process large volumes of raw hides, making it cost-effective for high-output tanneries.

Consistent use also reduces equipment corrosion and scaling, extending drum and pipe life. This lowers maintenance costs and supports long-term production stability.

Supply, Quality, and Best Practices

Tanneries prefer suppliers that provide high-purity caustic soda pearls with low salt and iron content. This is especially important for white and light-colored leathers. Proper packaging and dry storage help maintain product quality for several months.

Accurate dosing is critical. Using too much caustic soda can damage hide fibers and increase wastewater load. Many tanneries use automated dosing systems to control usage and recycle process water, reducing chemical loss and operating expenses.

Conclusion

Caustic Soda Pearls are a vital chemical in leather manufacturing, supporting key processes such as unhairing, degreasing, pH control, and finishing. Their strong alkalinity, easy handling, and consistent performance make them well suited for modern tanneries. When used correctly, caustic soda pearls improve processing efficiency, reduce safety risks, and help produce clean, high-quality leather while supporting cost control and environmental compliance.

Leave a Comment